0523-87962976

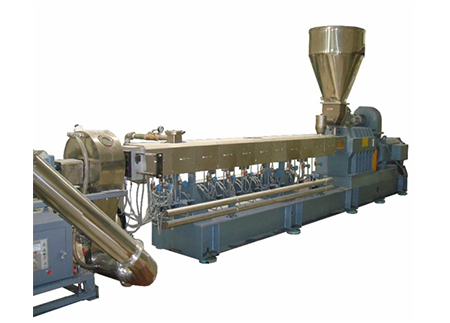

Production capacity: 130-150kg/hr(depends on different product formulation)

Product work flow scheme:

A. Task purpose: according to industrial art formula requirements: (1) make an accurate measurement feeding after premixing material resin and additives to make sure the accuracy of formula and stability of product quality; (2)complete muti component mix in twin screw extruder, continually compound and disperse until the material is stabilization to extruding pelletizing.

B. Feeding method: material resin and additives feeding; adopt twin screw metering feeder, feeding from the above of 1st barrel;

Main technical parameter:

1. Main extruder type: TDS-52B/600rpm-55kw-44:1;

2. Screw diameter: Ф51.4mm;

3. Main extruder L/D: 44:1;

4.Screw,barrel material: excellent nitriding steel(38CrMoAlA),through nitriding process;

5. Main motor power: 55kw(AC);

6.Main screw rotating speed : 60~600rpm;

7. Barrel heating power: ~29.4kw;

8. Total install power: ~95kw;

Tel : +86-25-52471902

Tel : +86-25-52471902  Fax : +86-25-52471902

Fax : +86-25-52471902 E-mail :

E-mail :  Add : No.212, Lantian Road, Lukou Street,

Add : No.212, Lantian Road, Lukou Street,